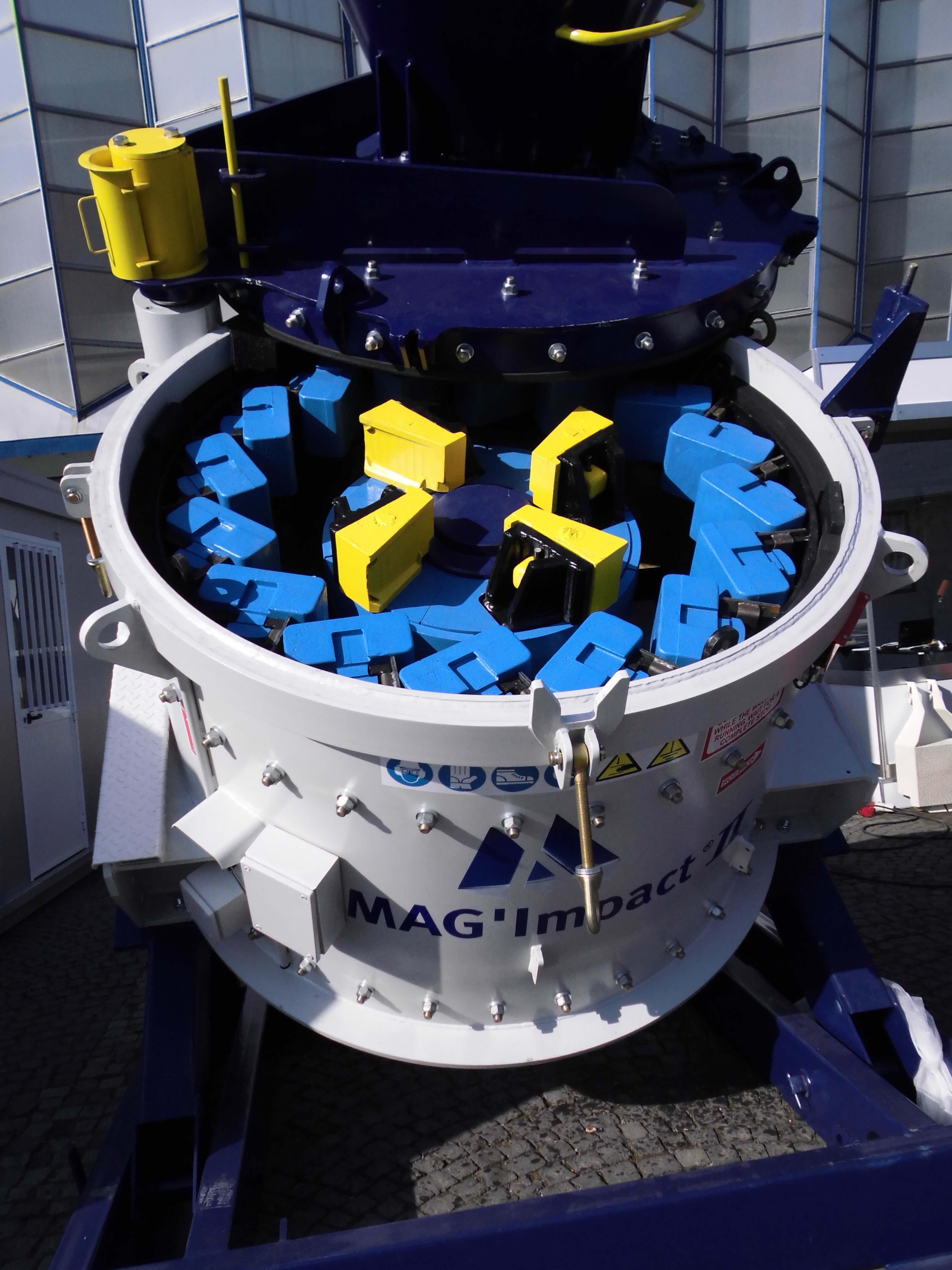

Crusher VSI -Vertical Shaft Impactor- MAG’Impact 2400

21 February, 2014

MAG’Impact is a high performance impact crusher entirely made by the group

MAGOTTEAUX.

MAG’Impact is a true VSI ( Vertical Shaft Impactor).

CHARACTERISTICS:

- highest cubic capacity for produced aggregates.

- easy to change crushing ratio, thus the equipment can be easy adjusted in order to respond to the demands of the process.

- constant product quality (dimension and shape), regardless of the wear degree and the produced quantity.

- high production capacity (up to 400 t/h).

- loading with material up to 130 mm.

- reasonable cost for wear, even when crushing abrasive materials.

- minimum discontinuance due to easy access to the spare parts.

- low energy consumption.

- high quality spare parts, designed to meet the work conditions.

- XWin : matrix for composite metals.

OPERATING PRINCIPLE:

- The material to be crushed is introduced into a crusher through the loading valve.

- It falls into a distributor resistant to wear located in the centre of the rotating board.

- The paddles situated on the rotating board send to the aggregates the necessary energy for them to be cast towards the anvils located on the peripheral ring.

- Different models of paddles and anvils are available depending on the material to be broken and on the breaking process.