Rollers for belt conveyors

25 June, 2013

Rollers for belt conveyors with diameter from Φ60 to Φ 159:

- steel idle rollers

- impact rollers with rubber rings used to reduce the impact of falling material in order to prevent belt damage.

- rollers with spaced anti-adhesion rings. Consist of a base roller and are used to sustain the belt on its return when used to transport sticky materials avoiding the build-up of crusty deposists wich may affect the regular forward movement of the belt.

- steel spiral cleaning rollers – are made from a base roller on wich two steel spirals are welded, parting from the centre to the right and left, and whose functions are to expel material to the sides of the belt.

- cleaning rollers with helical rings made from anti-abrasion rubber

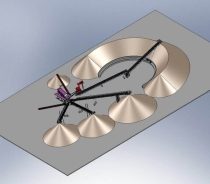

- steel cleaning rollers consist of two solid bearing housing joint by means of three 120 ° shafts on which two steel spirals are welded, originating from the centre with left and right helix. They are used in tacky material conveyors since their shape allows the material to fall through the roller too.

- belt – guide rollers

- flexible rollers

- hook stations that usually consist of 3 / 5 rollers – steel rollers or impact rollers with rubber rings